BPW Reasonable price China WVA29087 29181 Brake Disc for commercial truck

Detail

Analysis of Scratching Causes of Brake Pads and Brake Drums

1. The brake drum is a brittle gray cast iron material.

2. The brake drum is a cast iron piece with a shape similar to a tambourine, which is fixed with the tire and rotates at the same speed. When braking, hydraulic pressure is used to push the brake shoe to contact the inner edge of the brake drum, and the frictional force generated by the contact suppresses the rotation of the tire to achieve the purpose of braking. Drum brakes are composed of brake base plate, brake cylinder, brake shoes and other related connecting rods, springs, pins, and brake drums.

3. In order to ensure that the friction lining has a good braking torque, it is recommended to process the inner circular smooth hub of the brake hub when replacing the new friction lining, and the iron filings after processing must be cleaned up.

Specification

100% Crucial Dimension, Crack Detection

Complete Models for Different Vehicles

Tens of Different formulation to satisfied to different market

| Name | Outer Arc | Inner Arc | Width | Radius | Head Thickness | Current Thickness | Center Distance | Number of Holes | Through Hole | Large Aperture | Small Aperture | Total Chord Length of Hole | Hole Segmentation | Positioning Hole | Angle |

| W020-19032 | 220 | 204 | 180 | 203 | 10.5/17.5 | 10.5/17.5 | 130 | 10 | 16.5 | 8.5 | 160.16 | 41.09 | 19.67 | 180 | |

| W021-19094 | 220 | 204 | 200 | 203 | 10.5/17.5 | 10.9/17.1 | 150 | 10 | 16.5 | 8.5 | 160.16 | 41.09 | 19.67 | 180 | |

| W024-19581 | 195 | 175 | 222 | 201 | 15/18 | 15.5/18.2 | 92/180 | 8 | 16.5 | 8.5 | 134.18 | 45.55 | 17.01 | 180 | |

| W025-19582 | 235 | 218 | 222 | 201 | 9.0/18 | 9.2/17.8 | 92/180 | 10 | 16.5 | 8.5 | 177.43 | 45.86 | 19.19 | 180 | |

| W059-19487 | 192 | 177 | 182 | 200 | 13/17 | 13/17 | 92/140 | 8 | 16.5 | 16.5 | 8.5 | 133.8 | 45.38 | 20.4 | 180 |

| W060-19488 | 195 | 177 | 220 | 200 | 13/17 | 13/17 | 92/180 | 8 | 16.5 | 8.5 | 133.8 | 45.83 | 20.4 | 180 | |

| W071-4551a | 212 | 191 | 219 | 203 | 10.5/18.5 | 11.8/19 | 98.4/177.8 | 16 | 13 | 6.5 | 139 | 58.31 | 26.5 | 180 | |

| W072-4551c | 206 | 188 | 219 | 203 | 15.5/18.5 | 15.5/18.5 | 98.4/177.8 | 16 | 13 | 6.5 | 139 | 58.31 | 26.5 | 180 | |

| W108-L4705a | 196 | 177 | 177.8 | 185 | 11.2/18 | 11.2/18 | 79.38/136.52 | 14 | 13 | 6.5 | 126.55 | 53.1 | 25.42 | 150 | |

| W109-L4705c | 194 | 171 | 177.8 | 185 | 15.5/18.7 | 15.5/18.7 | 79.38/136.52 | 14 | 13 | 6.5 | 126.55 | 53.1 | 20.98 | 150 | |

| W137-19246 | 201 | 184 | 185 | 195 | 14.5 | 14.5 | 125 | 8 | 18.5 | 10.5 | 139.76 | 47.53 | 13.5 | 180 |

Model Table

|

Category |

No. |

Applicable models |

|

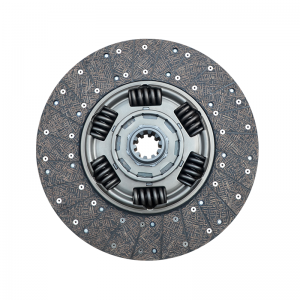

Clutch disc |

80010 |

Adaptation: Shaanxi Automobile Delong*6000 and other 500-580 horsepower |

|

80042 |

Adaptation: Dongfeng Tianlong flagship (small plate), etc., 310-500 horsepower | |

|

80047 |

Adaptation: Foton, Omark and other high-end light trucks | |

|

80076 |

Adaptation: Foton, JAC high-end light trucks | |

|

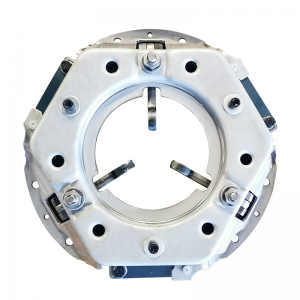

Clutch pressure plate |

90004 |

Adaptation: Dongfeng, Foton, Sinotruk, etc. 310-520 hp (Universal) |

|

90021 |

Jinlong, Yutong and other buses, XCMG, Weichai, Deutz, etc. | |

|

90044 |

Adaptation: 3 ton forklift (Forklift) | |

|

90069 |

Adaptation: Foton, JAC and other high-end light trucks | |

|

Drum brake pads |

4551 |

trailer |

|

4705 |

trailer | |

|

19032 |

BPW | |

|

19094 |

BPW | |

|

19246 |

Sinotruk | |

|

19487 |

North Benz | |

|

19488 |

North Benz | |

|

19581 |

After Dronman | |

|

19582 |

After Dronman | |

|

Disc brake pads |

5200 |

--- |

|

5300 |

--- | |

|

29087 |

North Benz, Scania, Shaanxi Heavy Truck | |

|

29228 |

BPW | |

|

DA05 |

Delong Bridge, Auman ETX | |

|

We have more than 2000 SKUs |

||

1. Annual production of 35 million pieces

2. Advanced and perfect material formula and front-end quality inspection big data center

3. Possess ISO14001/IATF16949 quality certificate; OE standard, CCC certified

Classification

Gifts Series

1. Environmentally friendly, non-asbestos and low metal formula

2. High friction coefficient, providing high braking force during use

3. Smooth braking

4. High cost performanceon various roads

High-end series

1. Environmentally friendly, non-asbestos and low metal formula

2. The friction coefficient is high and stable to ensure the safety of braking

3. Low wear rate and long service life

4. The friction surface is brushed with imported zebra-pattern glue, and the brake disc is cleaned during use to provide high initial grinding braking force